Quarries change size and shape on a daily basis as their mining progresses. While they get deeper and wider it’s not very common for their primary crusher to be relocated. Ultimately, a customer’s mining engineers will decide on the crusher’s future location, but we had some ideas.

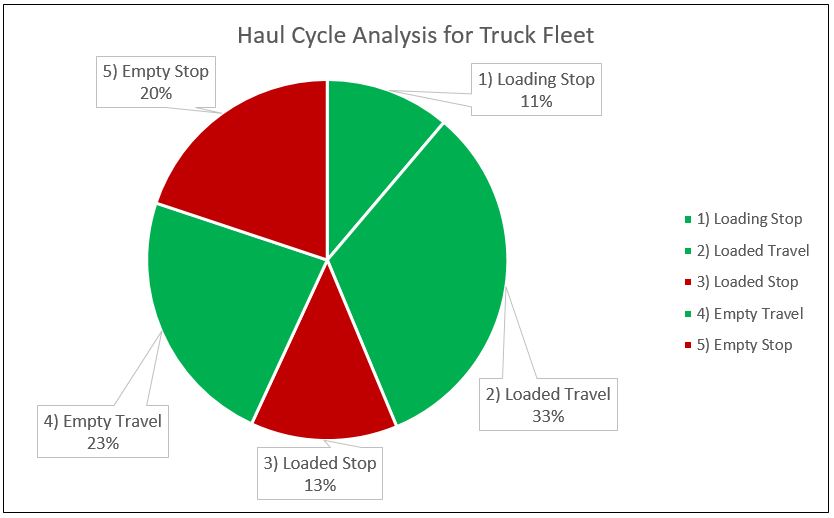

Our Business Solutions Group was invited out to a quarry as part of our Fleet Recommendation services and while we were there, we brought some interesting haul cycle data to light. In addition to payload, Komtrax Plus, the telematics system on their current fleet of Komatsu trucks, had been gathering useful information about how the trucks at this particular quarry spent their days.

Turns out that in the last year, up to 13% of the trucks’ time was spent waiting at the current crusher location. And up to 20% was spent waiting in line for a loader. That’s roughly 825 hours per year, per truck, of unproductive time related to mine design. This kind of limitation on productivity should definitely be considered as the crusher gets relocated.

We want to make sure that our customers get the most value possible out of their decision to do business with Komatsu. Telematics has many well-accepted benefits, but we are always on the lookout for new and creative insights like this.